Terminated Side Gusset Pouch Packaging

Terminated Side Gusset Pouches are suitable for big volume, great graphics, and heavy fills. With a flat bottom for stability and quad-sealed side gussets for maximum volume, the five display panels provide maximum shelf impact and brand awareness. Another benefit is that this pouch can run on a premade pouch machine. Get in touch with us to take a look at the machines we have for your Terminated Side Gusset Pouch Packaging!

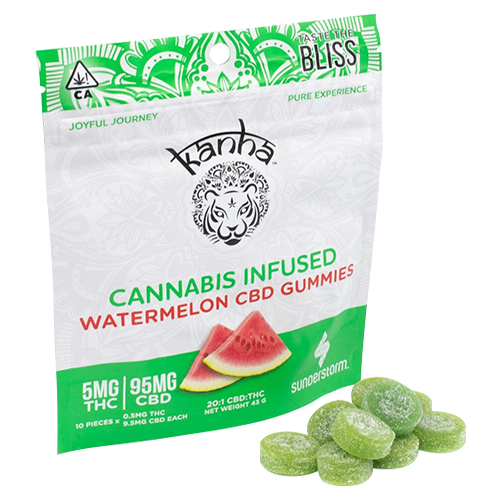

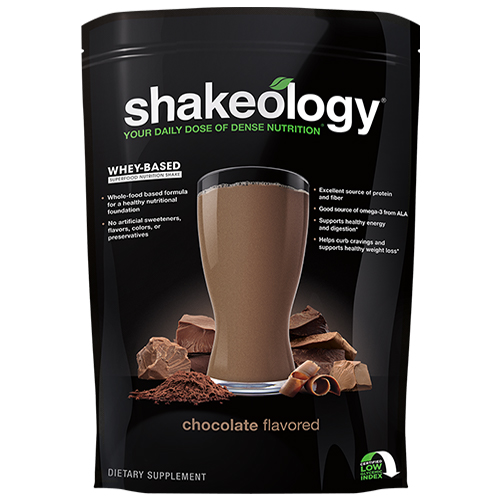

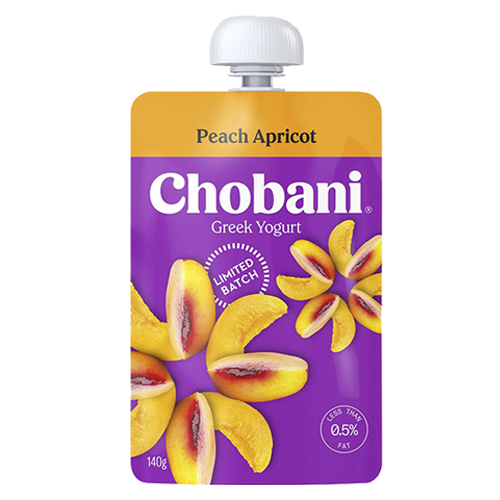

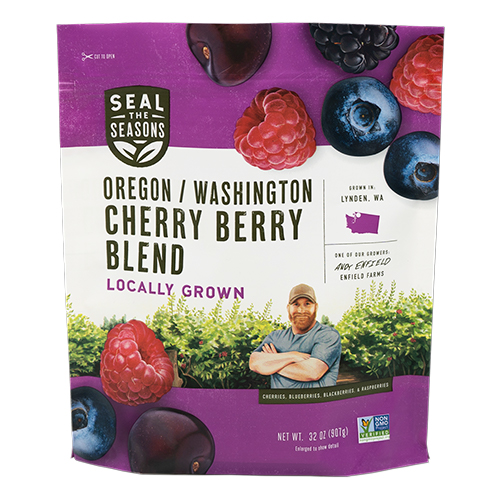

What is Terminated Side Gusset Pouch Packaging? A pouch that has a square bottom and side gussets that are sealed prior to the top. This pouch can hold heavy fills and large volumes of product.

This pouch is differentiated from a Quad-Seal Pouch (or Stabilo Bag) by its side gussets sealing into a flat seal which can allow for other customization features.

What Packaging Machine Will Fill This?

Stability

The Terminated Side Gusset pouch has a flat bottom that allows the packaging to remain upright on its own, even when it is empty. It will not fall over even as the contents decrease with usage.

More Efficient Loading

Due to the bags square bottom this packaging leaves no dead space when loaded with content. Shipping efficiency is also improved with the ability to make these bags shorter or narrower for the same content volume than a straitional standing bag. This trait also contributes to the cost reduction as they can be more efficiently displayed on the retailers’ shelves.

More Appealing Bags

This packaging offers a variety of printable surfaces. With the packaging wide faces and flat bottom that can easily hold vertical or horizontal designs. This allows for all four sides and the bottom to hold an eye catching design to increase appeal to consumers.

Numerous Options

Packaging has the ability to be manufactured for small (1kg or less) or large bags up to 10kg with a choice of closures.

Terminated Side Gusset

This style of pouch has side gussets which are terminated prior to the seal area and do not reach the top of the bag. Ideal for the PSG LEE and multiple Zipper options.

Non-Terminated Side Gusset

Non-Terminated Side Gusset: This bagging option has side gussets all the way to the top (un-terminated). The bag opening is large which allows for fast and efficient filling.

K-Flex has the machine for your terminated side gussett pouch packaging.

The PSG LEE Premade Pouch Packaging Machine is an excellent option for some Terminated Side Gusset Pouch Packaging. Reach out to let K-Flex help discover how this packaging machine's flexibility and high speeds result in greater efficiency. This machine uses premade pouches allowing for the most supreme quality in your finished pouch look. The flexibility of this machine is astounding with the touchscreen providing quick, easy changeover.

The SN: Horizontal Form-Fill-Seal machine is the way to go when you’re looking for a machine for your product. This machine is well-suited for both smaller and larger portions and sizes. SN is the global leader in Horizontal Form-Fill-Seal (HFFS) technology that specializes in high-speed production with guaranteed efficiencies. You can either use premade pouches on rails, or Rollstock to form the pouches. SN provides a premium, customized packaging solution for any speed in every industry that looks to use Terminated Side Gusset Pouch Packaging.