3-SIDE-SEAL POUCH Packaging

The 3-Side-Seal Pouch Packaging is similar not to be confused with the Satchet which seals all edges of the front and back panels. The front and back panels of the 3-Side-Seal pouch are sealed on three sides and folded on one. Generally, the bottom side of the bag is folded to allow the bag to flex for the product to settle at the bottom properly.

What is 3-Side-Seal Pouch Packaging? It is a package that is sealed on three sides with the remaining side folded. 3-Side-Seal Pouches are typically used for high-speed pouch packaging. The top seal can be customized to include holes, a tear notch, and other options. A very versatile, single-use pouch that can fit almost any kind or amount of product!

What Machine is best for your 3-side-seal pouch packaging?

The Most Economical

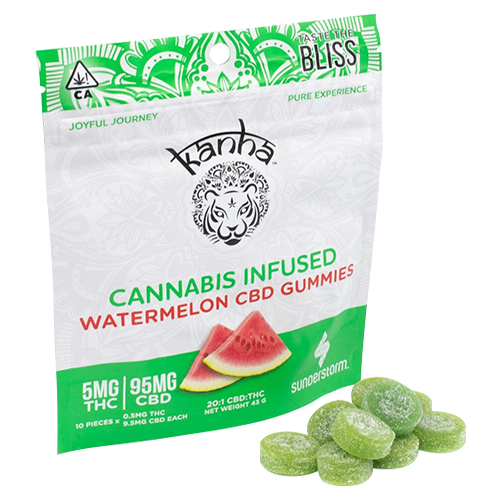

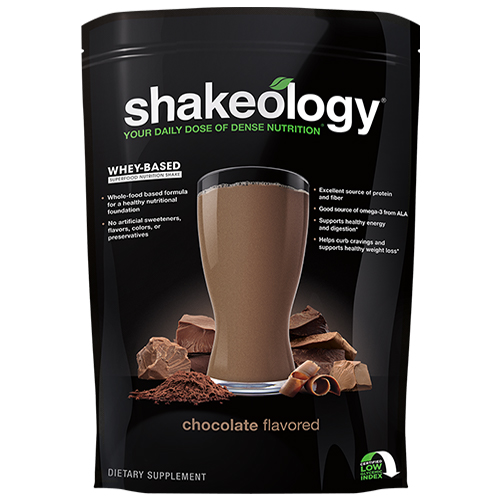

3-Side-Seal bags can be used for numerous products. Because of their simple shaped bags, they are considered to be the lowest cost to be used on a variety of products. They can also be combined with zippers for further added value.

Fast Production

Three Sided pouches are easy to make and fill making them one of the fastest, most economical type of pouch.

3-SIDE-SEAL POUCH

The 3-Side-Seal Pouch Packaging is a package that is sealed on three sides with the remaining side being folded. This type of packaging is typically used for high-speed runs. The top seal can be customized to include holes, a tear notch, and other options. A very versatile, single-use pouch that can fit almost any kind or amount of product!

K-Flex has the machine for your 3-side-seal pouch packaging needs.

The PSG LEE Premade Pouch Packaging Machine is an excellent option for certain 3-Side-Seal Pouch Packaging. Reach out to let K-Flex help discover how this packaging machine's flexibility and high speeds result in greater efficiency. This machine uses premade pouches allowing for the most supreme quality in your finished pouch look. The flexibility of this machine is astounding with the touchscreen providing quick, easy changeover.

The SN: Horizontal Form-Fill-Seal machine is the way to go when you’re looking for a machine for your product. This machine is well-suited for both smaller and larger portions and sizes. SN is the global leader in Horizontal Form-Fill-Seal (HFFS) technology that specializes in high-speed production with guaranteed efficiencies. You can either use premade pouches on rails, or Rollstock to form the pouches. SN provides a premium, customized packaging solution for any speed in every industry that looks to use 3-Side-Seal Pouch Packaging.