Corner-Fitment Stand-Up Pouch Packaging

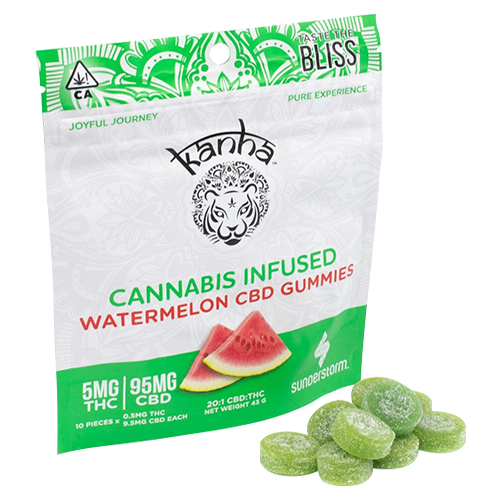

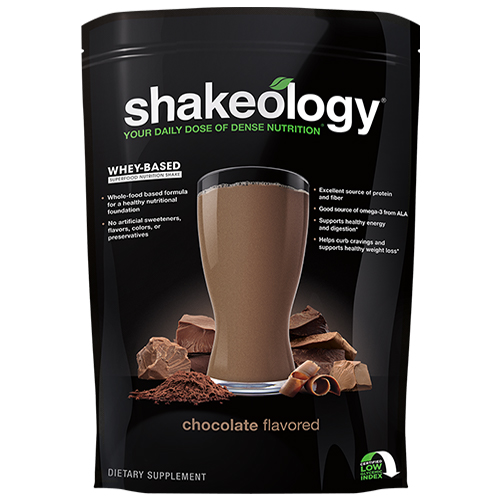

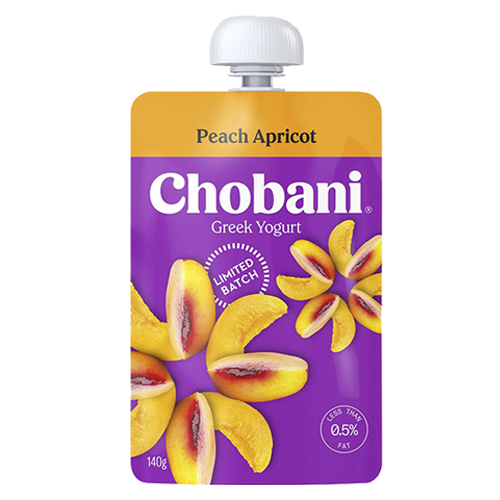

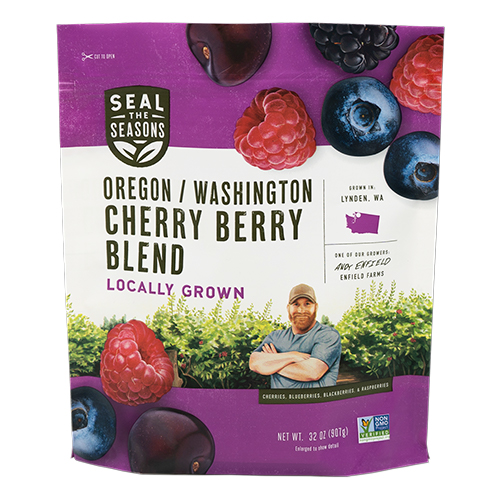

Corner-Fitment Stand-Up Pouch Packaging is becoming more common across many industries due to the advances in flexible packaging materials and consumer demand. There is a wide variety of spouts, caps, and fitments which allow consumers to pour and reclose with ease.

Corner-Fitment Stand-Up Pouches are convenient, clean, and easy to use with plenty of room for eye-catching graphics and materials. This lightweight package provides mess-free dispensing with 99% product evacuation.

What is a Corner-Fitment Stand Up-Pouch? A pouch with or without a bottom gusset using die-cut technology allowing customization and ergonomic shapes to be used with a wide variety of caps and spouts in the upper corner, much like the Center-Fitment Stand-Up Pouch.

What Machine is best for your corner-fitment stand-up pouch packaging?

Easy of Use

With the convenient spout at the top corner of the pouch you’re capable of easily pouring your product without having to worry about spilling. The flat bottom gusset also ensures that you can set it down safely and securely.

Sealed Tight

The reinforced heat-sealed laminated sides that these pouches have resulted in an incredibly high burst strength, so you can rest easy knowing that this pouch isn't going to rupture during shipping.

Great for Commerce

With the benefit of being portable, an aesthetically pleasing shape, and having a large surface area to print your label on there’s good reason these pouches have such a powerful shelf impact.

Variety

These pouches are capable of being outfitted with a wide variety of different spouts including child-friendly spouts. They also can be made in many different shapes.

Corner-Fitment Stand-Up Pouch

A Pouch with or without a bottom gusset using die-cut technology allowing customization and ergonomic shapes to be used with a wide variety of caps and spouts in the upper corner.

K-Flex has the right packaging machine for your corner-fitment stand-up pouches.

The PSG LEE Premade Pouch machine is an excellent option for certain Corner-Fitment Stand-Up Pouch Packaging. Reach out to let K-Flex help discover how this packaging machine's flexibility and high speeds result in greater efficiency. This machine uses premade pouches allowing for the most supreme quality in your finished pouch look. The flexibility of this machine is astounding with the touchscreen providing quick, easy changeover.

The SN: Horizontal Form-Fill-Seal machine is the way to go when you’re looking for a machine for your product. This machine is well-suited for both smaller and larger portions and sizes. SN is the global leader in Horizontal Form-Fill-Seal (HFFS) technology that specializes in high-speed production with guaranteed efficiencies. You can either use premade pouches on rails, or Rollstock to form the pouches. SN provides a premium, customized packaging solution for any speed in every industry that looks to use Corner-Fitment Stand-Up Pouch Packaging.